HS Series

Fully configurable, highly flexible pressure transmitter sub-system for HVAC applications

Offering the industry’s greatest flexibility, the HS Series DPT sub-system supports any custom configuration of pressure range, output configuration, bandwidth, etc. via a simple interface where you fully define and implement product features in minutes. Analog interfaces have been added with easy-to-use configuration software to accelerate product development while simplifying system calibration testing in manufacturing.

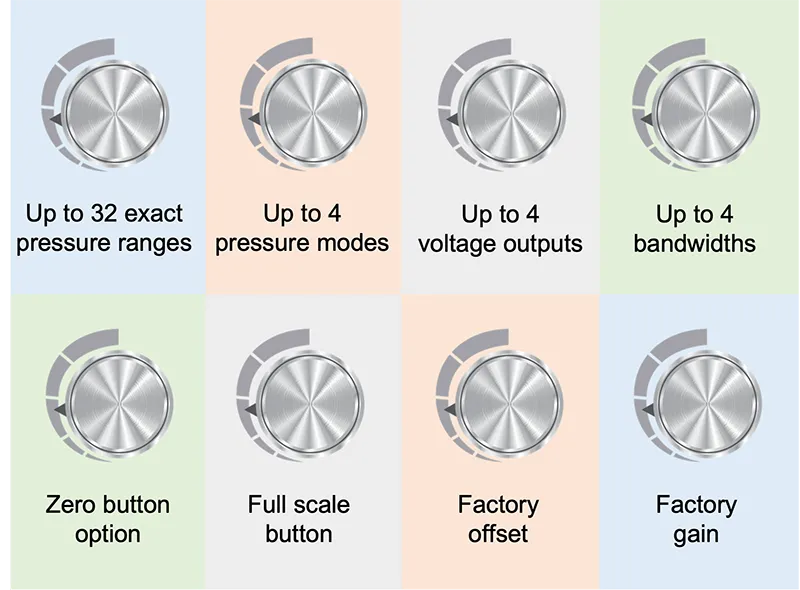

The same platform can be used to create a full featured pressure transmitter or a simple/dedicated pressure transmitter while retaining the capability to fully customize the product at the factory. With Multi-Range™ technology a single device can be customized to support any of 32 pressure ranges from as low as 25 Pa to 15 kPa with many field selectable features that can easily be customized at the factory without additional programming or hardware changes:

Evaluation Boards and Reference Platform

Common Device Features: 3.3V supply

Long-Term Stability is measured after first 12 months

Short-Term Error Band (STEB) is measured over 24 hours, after auto-zero

Common Specifications

- Supports full-featured pressure transmitter

- Up to 12 field selectable DIP Switch functions supported

- Up to 2 push button functions supported

- Factory programmable pressure ranges

- Up to 32 field selectable pressure ranges

- Up to 4 field selectable bandwidths

- Supports bidirectional/unidirectional/asymmetric outputs

- Supports 0-5/0-10/1-5/2-10 Volts outputs

- Integrated 50/60 Hz notch filter

- Temperature Compensated 0°C to 50°C

- Configuration software included

- Hardware reference platforms available

| Drawings and CAD Files | Version | Date | Download |

|---|---|---|---|

| SM02 Package for all HS Series (IGS and STEP files) | A | March 2023 |  |

| KP-ROR Package for Right Angle Adapters (STEP file) | A | February 2024 |  |

Download models in over 50 formats

| Data Sheet and Other Series Documentation | Version | Date | Download |

|---|---|---|---|

| DS-0004 HS Series Data Sheet | C | August 2024 |  |

| AN-0011 Data Sheet Definitions | A | February 2024 |  |

| AN-0010 Pressure Sensor Handling & Assembly Instructions | B | January 2025 |  |

| MB-0009 HS Series Infographic | A | April 2023 |  |

| PB-0008 HS Series Product Brief | B | April 2023 |  |

| PB-0009 HS Series Eval & Reference Platform Product Brief | A | April 2023 |  |

| Catalogs and Compliance Documentation | Version | Date | Download |

|---|---|---|---|

| PL-0001 Product Ordering Guide | X | May 2025 |  |

| MB-0001 NimbleSense Capabilities Brochure | B | April 2023 |  |

| MB-0004 Product Catalog | F | May 2025 |  |

| CS-0001 Certificate of RoHS Compliance | A | May 2019 |  |

| CS-0002 Statement of REACH Compliance (REACH-247) | D | May 2025 |  |

| CS-0003 Statement on Use of Conflict Minerals | A | May 2019 |  |

| CS-0006 Certificate of California Proposition 65 Compliance | A | May 2019 |  |

Target Markets

- DPT (Differential Pressure Transmitters)

Stay informed!

Sign-up to receive the latest

HS Series updates.

HS Series Benefits Summary